Vedi le specifiche per i dettagli del prodotto.

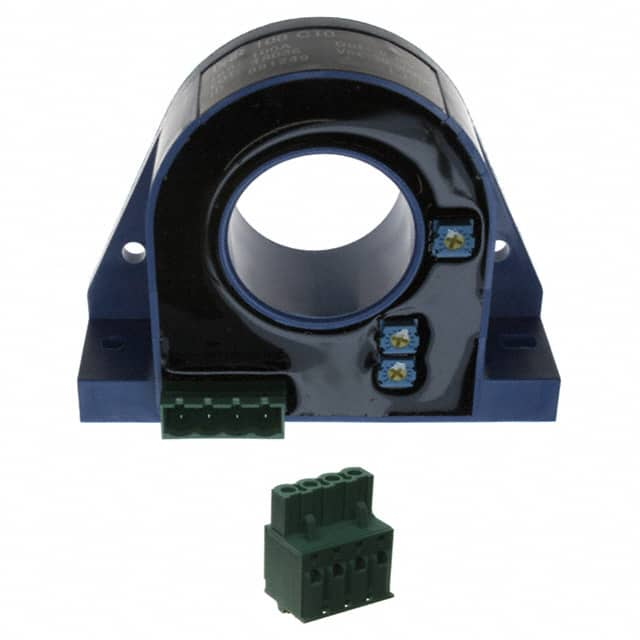

DHR 100 C10

Product Overview

The DHR 100 C10 belongs to the category of electronic components and is primarily used as a voltage regulator in various electronic devices. Its characteristics include high efficiency, low power consumption, and stable output voltage. The package consists of a small form factor with essential heat dissipation features. The essence of the DHR 100 C10 lies in its ability to provide reliable voltage regulation in compact electronic designs. It is typically packaged individually and is available in varying quantities based on consumer needs.

Specifications

- Input Voltage Range: 4V to 30V

- Output Voltage: 3.3V

- Maximum Output Current: 1A

- Operating Temperature Range: -40°C to 125°C

- Package Type: TO-220

- Thermal Resistance: 50°C/W

Detailed Pin Configuration

The DHR 100 C10 has three pins: 1. Input (Vin) 2. Ground (GND) 3. Output (Vout)

Functional Features

- Overcurrent Protection

- Thermal Shutdown

- Short Circuit Protection

- Low Dropout Voltage

Advantages and Disadvantages

Advantages - High Efficiency - Wide Input Voltage Range - Compact Design - Robust Protection Features

Disadvantages - Limited Output Current - Higher Thermal Resistance

Working Principles

The DHR 100 C10 operates by regulating the input voltage to a stable 3.3V output using internal circuitry. When the input voltage fluctuates, the regulator adjusts the output to maintain a constant voltage level, ensuring consistent power supply to connected devices.

Detailed Application Field Plans

The DHR 100 C10 is commonly used in portable electronic devices such as handheld instruments, battery-powered equipment, and IoT devices. Its stable output voltage and compact size make it suitable for applications where space and power efficiency are crucial.

Detailed and Complete Alternative Models

- LM1117

- XC6206

- AMS1117

In conclusion, the DHR 100 C10 is a versatile voltage regulator with a wide range of applications, offering stable and efficient power management in compact electronic designs.

Word count: 287

10 domande e risposte comuni relative all'applicazione di DHR 100 C10 nelle soluzioni tecniche

What is DHR 100 C10?

- DHR 100 C10 is a high-performance industrial adhesive and sealant commonly used in technical solutions.

What are the key features of DHR 100 C10?

- DHR 100 C10 offers excellent adhesion, chemical resistance, and durability, making it suitable for various technical applications.

How is DHR 100 C10 applied?

- DHR 100 C10 can be applied using standard caulking guns or dispensing equipment, and it cures at room temperature.

What materials can DHR 100 C10 bond to?

- DHR 100 C10 can bond to a wide range of substrates including metals, plastics, glass, and ceramics.

Is DHR 100 C10 suitable for outdoor applications?

- Yes, DHR 100 C10 is designed to withstand outdoor conditions and is resistant to UV exposure and weathering.

What is the recommended curing time for DHR 100 C10?

- The curing time for DHR 100 C10 varies depending on environmental conditions, but typically ranges from 24 to 72 hours.

Can DHR 100 C10 be painted over?

- Yes, DHR 100 C10 can be painted once it has fully cured, allowing for seamless integration into various technical solutions.

Is DHR 100 C10 suitable for use in high-temperature environments?

- DHR 100 C10 has a high-temperature resistance, making it suitable for applications where heat resistance is required.

Does DHR 100 C10 require special handling or storage?

- DHR 100 C10 should be stored in a cool, dry place and protected from direct sunlight. It does not require any special handling procedures.

Is DHR 100 C10 compliant with industry standards and regulations?

- Yes, DHR 100 C10 complies with relevant industry standards and regulations, ensuring its suitability for technical solutions across various sectors.