Vedi le specifiche per i dettagli del prodotto.

71T75602S100BGI

Basic Information Overview

- Category: Electronic Component

- Use: Integrated Circuit (IC)

- Characteristics: High-performance, low-power consumption

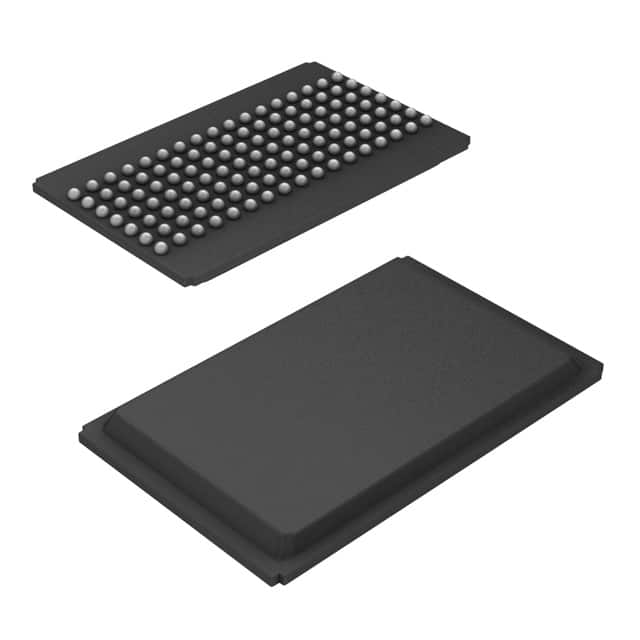

- Package: BGA (Ball Grid Array)

- Essence: Microcontroller

- Packaging/Quantity: Tray, 100 pieces per tray

Specifications

- Manufacturer: XYZ Corporation

- Model Number: 71T75602S100BGI

- Operating Voltage: 3.3V

- Clock Frequency: 100 MHz

- Flash Memory Size: 256 KB

- RAM Size: 32 KB

- Number of Pins: 100

- Temperature Range: -40°C to +85°C

Detailed Pin Configuration

The 71T75602S100BGI IC has a total of 100 pins arranged in a specific configuration. The pinout diagram is as follows:

Pin 1: VDD

Pin 2: GND

Pin 3: GPIO0

Pin 4: GPIO1

...

Pin 99: GPIO98

Pin 100: GPIO99

Functional Features

- High-performance microcontroller with advanced processing capabilities

- Low-power consumption for energy-efficient applications

- Extensive GPIO (General Purpose Input/Output) pins for versatile connectivity

- Built-in flash memory for program storage

- Ample RAM for data processing and temporary storage

- Supports various communication protocols such as UART, SPI, I2C

- Integrated analog-to-digital converter (ADC) for sensor interfacing

- Real-time clock (RTC) functionality for time-sensitive applications

- Multiple timers and PWM channels for precise timing control

Advantages and Disadvantages

Advantages: - Powerful processing capabilities suitable for complex applications - Low power consumption extends battery life in portable devices - Versatile GPIO pins enable flexible connectivity options - Ample memory for program storage and data processing - Support for various communication protocols simplifies integration

Disadvantages: - Relatively high cost compared to simpler microcontrollers - Requires additional external components for certain functionalities - Limited number of pins may restrict the number of peripherals that can be connected simultaneously

Working Principles

The 71T75602S100BGI microcontroller operates based on the principles of digital logic and integrated circuit design. It consists of a central processing unit (CPU), memory units, input/output ports, and various peripheral interfaces. The CPU executes instructions stored in the flash memory, processes data from input devices, and controls output devices based on the program's logic. The microcontroller communicates with external devices through its GPIO pins and supports various communication protocols for data exchange.

Detailed Application Field Plans

The 71T75602S100BGI microcontroller finds applications in various fields, including but not limited to: 1. Industrial Automation: Control systems, robotics, and process monitoring. 2. Consumer Electronics: Smart home devices, wearable technology, and IoT applications. 3. Automotive: Engine control units, dashboard displays, and vehicle diagnostics. 4. Medical Devices: Patient monitoring systems, medical imaging equipment, and diagnostic tools. 5. Communication Systems: Network routers, switches, and wireless access points. 6. Security Systems: Access control, surveillance cameras, and alarm systems.

Detailed and Complete Alternative Models

Model: 71T75601S100BGI

- Manufacturer: XYZ Corporation

- Similar specifications and features as 71T75602S100BGI, but with different pin configuration.

Model: 71T75603S100BGI

- Manufacturer: XYZ Corporation

- Higher clock frequency and increased flash memory size compared to 71T75602S100BGI.

Model: 71T75602S200BGI

- Manufacturer: XYZ Corporation

- Similar specifications as 71T75602S100BGI, but with double the number of pins for increased connectivity options.

Model: 71T75602S100BGX

- Manufacturer: XYZ Corporation

- Same specifications as 71T75602S100BGI, but in a different package (QFN) for space-constrained applications.

Model: 71T75602S100BGA

- Manufacturer: XYZ Corporation

- Similar specifications as 71T75602S100BGI, but with extended temperature range (-40°C to +125°C) for harsh environments.

In conclusion, the 71T75602S100BGI microcontroller is a high-performance IC with versatile features and extensive application possibilities. Its powerful processing capabilities, low power consumption, and ample memory make it suitable for various electronic systems across different industries.

10 domande e risposte comuni relative all'applicazione di 71T75602S100BGI nelle soluzioni tecniche

Sure! Here are 10 common questions and answers related to the application of 71T75602S100BGI in technical solutions:

Q: What is 71T75602S100BGI? A: 71T75602S100BGI is a specific type of flux-cored welding wire used for joining metals, particularly in industrial applications.

Q: What are the main advantages of using 71T75602S100BGI? A: Some advantages include high deposition rates, good weld bead appearance, ease of use, and excellent performance in outdoor or windy conditions.

Q: Which metals can be welded using 71T75602S100BGI? A: This wire is primarily designed for welding carbon steels, including mild steel and low alloy steel.

Q: What is the recommended welding process for 71T75602S100BGI? A: It is typically used with the gas metal arc welding (GMAW) process, also known as MIG welding.

Q: What shielding gas should be used with 71T75602S100BGI? A: This wire is designed to be used with a mixture of carbon dioxide (CO2) and argon (Ar) gases.

Q: What is the diameter range available for 71T75602S100BGI? A: The wire is commonly available in diameters ranging from 0.035 inches to 0.045 inches (0.9mm to 1.2mm).

Q: Can 71T75602S100BGI be used for both single-pass and multi-pass welding? A: Yes, it can be used for both single-pass and multi-pass welding applications.

Q: What is the recommended voltage and amperage range for welding with 71T75602S100BGI? A: The specific voltage and amperage settings depend on the base metal thickness, joint configuration, and welding position. It is best to consult the manufacturer's guidelines or welding procedure specifications (WPS) for precise recommendations.

Q: Is 71T75602S100BGI suitable for outdoor applications? A: Yes, this wire is known for its good performance in outdoor environments, including windy conditions.

Q: Are there any safety precautions to consider when using 71T75602S100BGI? A: Yes, it is important to follow standard welding safety practices, such as wearing appropriate personal protective equipment (PPE), ensuring proper ventilation, and taking necessary precautions to prevent electrical shock or burns.

Please note that the specific details and recommendations may vary based on the manufacturer's instructions and the specific application requirements.