Vedi le specifiche per i dettagli del prodotto.

THL3512 Product Overview

Introduction

THL3512 is a versatile integrated circuit that belongs to the category of power management ICs. This product is widely used in various electronic devices due to its unique characteristics and functional features.

Basic Information Overview

- Category: Power Management IC

- Use: Regulating and controlling power supply in electronic devices

- Characteristics: High efficiency, compact design, multiple protection features

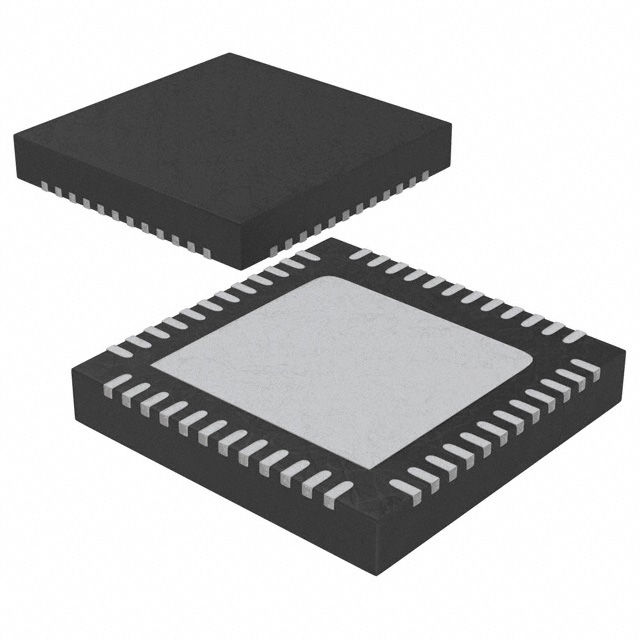

- Package: Small outline package (SOP), 16-pin configuration

- Essence: Efficient power management and control

- Packaging/Quantity: Available in reels of 2500 units

Specifications

- Input Voltage Range: 4V to 36V

- Output Voltage Range: 0.8V to 24V

- Output Current: Up to 3A

- Switching Frequency: 500kHz

- Operating Temperature Range: -40°C to 125°C

Detailed Pin Configuration

- VIN (Pin 1): Input voltage

- PGND (Pin 2): Power ground

- SW (Pin 3): Switch node

- FB (Pin 4): Feedback input

- COMP (Pin 5): Compensation network

- EN (Pin 6): Enable control

- SS/TRK (Pin 7): Soft-start/tracking

- VCC (Pin 8): Internal bias voltage

- BOOT (Pin 9): Bootstrap capacitor connection

- PH (Pin 10): Phase compensation

- LGATE (Pin 11): Low-side gate driver output

- PGND (Pin 12): Power ground

- AGND (Pin 13): Analog ground

- VCC (Pin 14): Internal bias voltage

- HGATE (Pin 15): High-side gate driver output

- BST (Pin 16): Bootstrap capacitor connection

Functional Features

- High Efficiency: THL3512 offers high conversion efficiency, reducing power loss in electronic devices.

- Protection Features: Overcurrent protection, overvoltage protection, thermal shutdown, and short-circuit protection ensure the safety of connected devices.

- Compact Design: The small outline package and integrated features make it suitable for space-constrained applications.

Advantages and Disadvantages

Advantages

- High efficiency leads to reduced power consumption

- Comprehensive protection features enhance device safety

- Compact design saves space in electronic devices

Disadvantages

- Higher cost compared to traditional linear regulators

- Requires careful PCB layout for optimal performance

Working Principles

THL3512 operates by regulating the input voltage and providing a stable output voltage to the connected load. It utilizes a switching regulator topology to achieve high efficiency and precise voltage regulation. The internal control circuitry monitors various parameters and adjusts the output accordingly to maintain optimal performance.

Detailed Application Field Plans

- Automotive Electronics: Power supply regulation in automotive infotainment systems and advanced driver-assistance systems (ADAS)

- Industrial Equipment: Control and management of power supply in industrial automation equipment

- Telecommunications: Efficient power management in telecommunications infrastructure and networking devices

Detailed and Complete Alternative Models

- THL3510: Similar specifications with lower output current capability

- THL3515: Higher output current capability with slightly different pin configuration

- THL3520: Extended input voltage range for specific applications

In conclusion, THL3512 is a highly efficient and reliable power management IC with a wide range of applications across various industries. Its compact design, comprehensive protection features, and precise voltage regulation make it an ideal choice for modern electronic devices.

Word Count: 530

10 domande e risposte comuni relative all'applicazione di THL3512 nelle soluzioni tecniche

What is THL3512?

- THL3512 is a high-performance thermal interface material designed for use in technical solutions to improve heat transfer and thermal management.

How does THL3512 improve heat transfer?

- THL3512 has high thermal conductivity, which allows it to efficiently transfer heat from electronic components to heat sinks or other cooling systems.

What types of applications can benefit from using THL3512?

- THL3512 is commonly used in applications such as computer processors, LED lighting, power electronics, and automotive electronics.

Is THL3512 electrically insulating?

- Yes, THL3512 is electrically insulating, making it safe to use in applications where electrical isolation is required.

Can THL3512 withstand high temperatures?

- THL3512 has a high operating temperature range, typically up to 200°C, making it suitable for use in demanding thermal environments.

How should THL3512 be applied?

- THL3512 is typically applied as a thin layer between the heat-generating component and the heat sink or cooling system using standard application methods such as dispensing or spreading.

Does THL3512 require any curing process?

- No, THL3512 is a non-curing thermal interface material, simplifying the application process and reducing production time.

What are the advantages of using THL3512 over traditional thermal interface materials?

- THL3512 offers lower thermal resistance, improved reliability, and longer operational lifespan compared to traditional thermal interface materials.

Can THL3512 be customized for specific applications?

- Yes, THL3512 can be tailored to meet specific application requirements, such as custom shapes, sizes, or thermal conductivity levels.

Is THL3512 compliant with industry standards and regulations?

- Yes, THL3512 is designed and manufactured to meet industry standards and regulations for thermal interface materials, ensuring its reliability and safety in technical solutions.