Vedi le specifiche per i dettagli del prodotto.

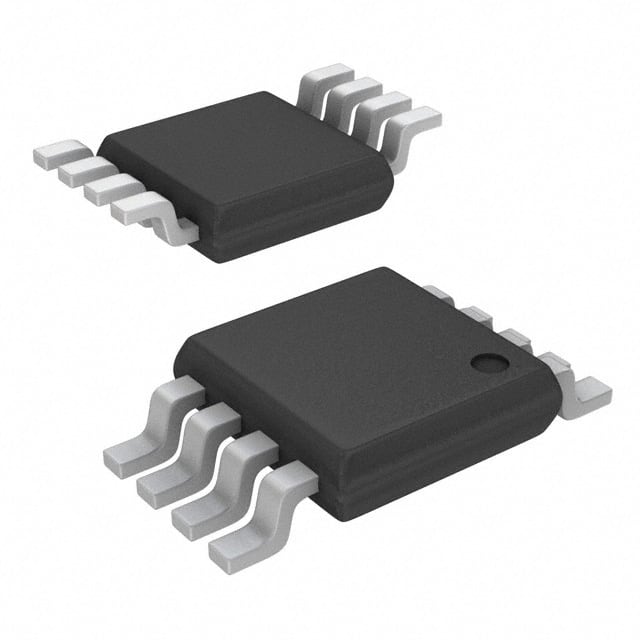

AS1743G

Product Overview

- Category: Integrated Circuit

- Use: Signal Amplification and Processing

- Characteristics:

- High gain and low noise

- Wide frequency range

- Small package size

- Low power consumption

- Package: SOP-8 (Small Outline Package)

- Essence: The AS1743G is a high-performance integrated circuit designed for signal amplification and processing applications.

- Packaging/Quantity: Available in reels of 2500 units.

Specifications

- Supply Voltage: 2.7V to 5.5V

- Operating Temperature: -40°C to +85°C

- Gain Bandwidth Product: 10 MHz

- Input Offset Voltage: ±1 mV

- Input Bias Current: ±50 nA

- Output Current: ±20 mA

- Slew Rate: 4 V/µs

- Quiescent Current: 2.5 mA

Detailed Pin Configuration

The AS1743G features an SOP-8 package with the following pin configuration:

- V- (Negative Power Supply)

- IN- (Inverting Input)

- IN+ (Non-Inverting Input)

- V+ (Positive Power Supply)

- OUT (Output)

- NC (No Connection)

- NC (No Connection)

- GND (Ground)

Functional Features

- High voltage gain and low noise figure make it suitable for sensitive signal amplification.

- Wide frequency range allows for versatile applications in various electronic systems.

- Small package size enables space-saving designs.

- Low power consumption ensures energy efficiency.

Advantages

- High gain and low noise improve signal quality.

- Wide frequency range provides flexibility in different applications.

- Small package size allows for compact circuit designs.

- Low power consumption reduces energy usage.

Disadvantages

- Limited output current may not be suitable for high-power applications.

- Single-channel configuration limits simultaneous amplification of multiple signals.

Working Principles

The AS1743G operates as a voltage amplifier by amplifying the input signal with high gain and low noise. It utilizes a differential amplifier configuration to provide both inverting and non-inverting inputs, allowing flexibility in signal processing. The integrated circuit is designed to operate within a specified supply voltage range and temperature range.

Detailed Application Field Plans

The AS1743G can be used in various applications, including:

- Audio Amplifiers

- Sensor Signal Conditioning

- Communication Systems

- Medical Devices

- Test and Measurement Equipment

Detailed and Complete Alternative Models

- AS1742G: Similar specifications and pin configuration, but with lower gain bandwidth product.

- AS1744G: Similar specifications and pin configuration, but with higher output current capability.

- AS1745G: Similar specifications and pin configuration, but with wider operating temperature range.

These alternative models offer similar functionality to the AS1743G but may have slight variations in performance or additional features.

In conclusion, the AS1743G is a versatile integrated circuit that provides high gain and low noise amplification for various signal processing applications. Its small package size and low power consumption make it suitable for space-constrained and energy-efficient designs. However, its limited output current and single-channel configuration should be considered for specific high-power or multi-signal amplification requirements.

10 domande e risposte comuni relative all'applicazione di AS1743G nelle soluzioni tecniche

Sure! Here are 10 common questions and answers related to the application of AS1743G in technical solutions:

Q: What is AS1743G? A: AS1743G is a technical standard developed by the Australian Standards committee that provides guidelines for the application of electrical equipment in hazardous areas.

Q: What is the purpose of AS1743G? A: The purpose of AS1743G is to ensure the safe installation, operation, and maintenance of electrical equipment in hazardous areas to prevent accidents and minimize the risk of explosions or fires.

Q: Which industries does AS1743G apply to? A: AS1743G applies to various industries such as oil and gas, chemical processing, mining, pharmaceuticals, and any other industry where flammable substances are present.

Q: What are hazardous areas? A: Hazardous areas are locations where flammable gases, vapors, liquids, or combustible dusts are present in sufficient quantities to create a fire or explosion hazard.

Q: How does AS1743G classify hazardous areas? A: AS1743G classifies hazardous areas into different zones based on the likelihood and duration of the presence of flammable substances. These zones range from Zone 0 (highest risk) to Zone 2 (lowest risk).

Q: What are some key requirements of AS1743G? A: Some key requirements include proper equipment selection, installation, inspection, testing, and maintenance procedures to ensure compliance with safety standards in hazardous areas.

Q: Who is responsible for complying with AS1743G? A: It is the responsibility of the equipment manufacturers, installers, operators, and maintenance personnel to comply with AS1743G and ensure the safety of electrical equipment in hazardous areas.

Q: What are some common types of electrical equipment covered by AS1743G? A: Common types of electrical equipment covered by AS1743G include lighting fixtures, motors, switches, control panels, cables, connectors, and other devices used in hazardous areas.

Q: How often should inspections and maintenance be conducted for electrical equipment in hazardous areas? A: Inspections and maintenance should be conducted regularly as per the manufacturer's recommendations and any applicable regulations or industry standards.

Q: Are there any specific training requirements for personnel working with electrical equipment in hazardous areas? A: Yes, AS1743G recommends that personnel working with electrical equipment in hazardous areas receive appropriate training to understand the risks, safety procedures, and proper handling of such equipment.

Please note that these answers provide a general overview and it is important to refer to the actual AS1743G standard for detailed and specific information.